Why is differential pressure of utmost significance in the measurement of a fan's air flow?

1. Measurement Methodology

In the measurement of air flow rate and static pressure, the AMCA (Air Movement and Control Association) standards were employed, with the dual-chamber method being the predominant measurement technique. This methodology operates by generating a pressure differential (Pn) between two chambers (Chamber A and Chamber B), subsequently utilizing this differential pressure to calculate the air flow rate. The pressure differential, defined as the variance in pressure between Chamber A and Chamber B, exhibits a significant correlation with the air flow rate.

Measurement Principle:

The dual-chamber method establishes a pressure differential between the two chambers, and through precise measurement of this pressure differential (Pn), the air flow rate is derived. This measurement approach ensures the accuracy and reliability of the testing process.

2. Maximum Air Flow Rate

When the nozzle is open and the auxiliary Fan is in use, and the static pressure (Ps) is adjusted to zero, the pressure difference (Pn) between Chamber A and Chamber B reaches its maximum value. At this point, the air flow rate also reaches its maximum. The air flow rate at this time can be calculated using the following formula (A):

Q = 0.6 × A × V

Where: •

Q represents the air flow rate (unit: m³/min); •

A represents the nozzle cross-sectional area (unit: m²), and its calculation formula is:

A = 4π × D²

Where D is the nozzle diameter. •

V is the average flow velocity at the nozzle outlet (unit: m/s), and its calculation formula is: V=F2×PnV = \frac{F}{2 \times Pn}V=2×PnF

Here, F represents the specific weight of air (unit: kg/m³). At 20°C and 1 atmosphere pressure, the specific weight of air is 1.2 kg/m³. g is the acceleration due to gravity (9.8 m/s²), and Pn is the differential pressure (unit: mm H₂O).

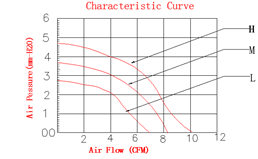

3. The Significance of Differential Pressure

Why is differential pressure crucial? Differential pressure serves as a fundamental parameter in air flow measurement, as it directly influences both flow velocity (V) and the resultant air flow rate (Q). An increase in differential pressure leads to a corresponding increase in both flow velocity and air flow rate, and vice versa. Precise measurement of differential pressure is essential for evaluating fan performance.

The calculation of differential pressure is as follows:

Pn = P_chamberA - P_chamberB

Where:

P_chamberA represents the pressure in Chamber A;

P_chamberB denotes the pressure in Chamber B.

4. Maximum Static Pressure

Another critical parameter associated with maximum airflow is the maximum static pressure. When the nozzle is closed, the pressure in chamber A reaches its peak value. The difference (Ps) between the pressure in chamber A and the ambient air pressure at this point represents the maximum static pressure.

The measurement of maximum static pressure serves as another essential indicator of fan performance, particularly in assessing the resistance that the fan can overcome. Maximum static pressure is not only related to the design of the fan but also closely associated with the relationship between flow rate, nozzle design, and differential pressure.

5. Role of Auxiliary Fans

The role of auxiliary fans cannot be overlooked during measurements. Auxiliary fans help counteract aerodynamic resistance, thereby ensuring measurement accuracy. Without auxiliary fans, the fan's output may be affected by resistance, leading to inaccurate measurement results. Therefore, auxiliary fans play a crucial role in maintaining a stable testing environment and mitigating external interferenc

5. The Role of the Auxiliary Fan

The significance of the auxiliary fan during measurement procedures cannot be overstated. The auxiliary fan serves to counteract aerodynamic resistance, thereby ensuring the precision of measurements. In the absence of an auxiliary fan, the fan's output may be adversely affected by resistance, potentially leading to inaccurate measurement results. Consequently, the auxiliary fan plays a crucial role in maintaining a stable testing environment and mitigating external interferences.

6. Application Scenarios

The dual-chamber measurement method is widely employed across various industrial and commercial applications, particularly in scenarios requiring precise evaluation of fan performance. Key application domains include:

• Ventilation Systems: Utilized for assessing airflow and static pressure in ventilation equipment to ensure optimal ventilation efficacy;

• Air Conditioning Systems: Applied to measure airflow and pressure characteristics of fans within HVAC systems, thereby enhancing cooling efficiency;

• Industrial Equipment: In industrial applications, accurate measurement of fan airflow and static pressure is crucial for ensuring proper equipment operation and thermal management.

Through precise measurement of airflow and static pressure under diverse operating conditions, this method enables effective prediction of equipment thermal performance and provides critical data support for system optimization.

7. Conclusion

Differential pressure plays a pivotal role in fan airflow measurement. It directly influences airflow calculation and serves as a core parameter in fan performance testing. The dual-chamber method, combined with precise differential pressure measurement and auxiliary fan regulation, provides reliable data support for fan performance evaluation. Understanding the relationship between differential pressure and airflow is crucial for enhancing system efficiency and optimizing equipment performance across various applications, including ventilation, air conditioning, and industrial equipment.