Why choose a centrifugal fan that bends backwards?

How does a backward-curved centrifugal Fan operate?

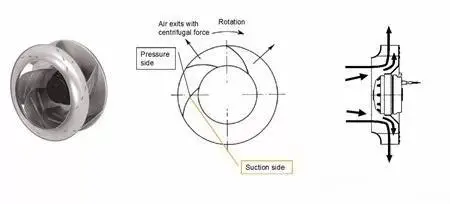

The term "centrifugal fan" originates from the radial airflow generated from the outer periphery of the fan. A backward-curved centrifugal fan is distinguished by its cylindrical structure, multiple large curved blades, and conical inlet nozzle. In the illustrated example, the fan rotates in a clockwise direction.

As the fan rotates, a pressure differential is established across the impeller blades. On the convex side of the impeller blade, rotation generates a force that creates positive pressure, pushing air outward in a radial direction. Conversely, on the concave side of the impeller blades, rotation induces negative pressure, which draws air into the spaces between the blades. This process continues as the air is subsequently propelled outward by the succeeding blades. The suction side of the impeller blade draws air from the center of the fan, resulting in a 90-degree change in airflow direction from the inlet to the exhaust port.

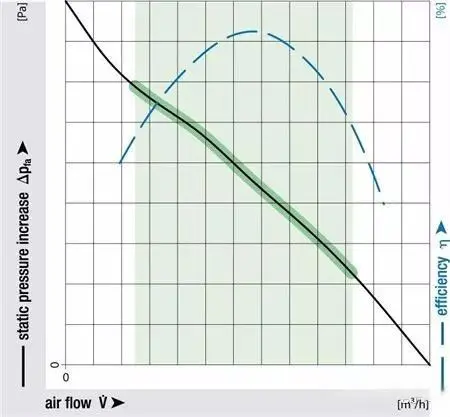

Blower Fan characteristics:

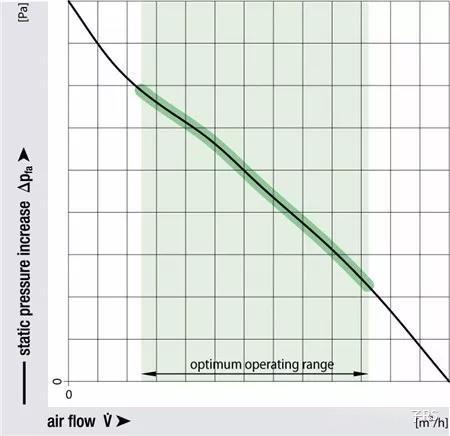

The optimal operating range for a backward-curved centrifugal fan lies within the midsection of its performance curve. When operating at intermediate pressure and flow rates, this type of fan exhibits peak efficiency and stability. The following diagram illustrates the optimal operating region...

The volume flow rate is plotted along the X-axis, while the system pressure is represented on the Y-axis. In the absence of system pressure (when the fan operates freely), a backward-curved centrifugal fan achieves the highest volumetric flow rate. On both the suction and exhaust sides of the fan, the volumetric flow rate diminishes due to resistance encountered. Peak efficiency occurs at the midpoint of the characteristic curve, where the ratio of output power (volumetric flow rate [m³/s] multiplied by static pressure [Pa]) to input power (W) is maximized, and the sound pressure generated by the fan is minimized. Operating outside this optimal range results in increased noise levels and reduced system efficiency. A key advantage of employing a backward-curved electric impeller lies in its lack of a blocked turning point, meaning that every point on the fan's performance curve can be safely operated. Additionally, this type of impeller exhibits the highest static efficiency among all fan types and airflow generation mechanisms, making it suitable for use in inflation chambers or integration into confined spaces to direct airflow outward. In contrast, other fan types, such as axial, diagonal, and forward-curved centrifugal fans, possess regions that are less desirable. These areas may induce turbulence, which can negatively impact the long-term reliable operation of the fan.