What is the typical lifespan specification for the cooling fan in a frequency converter?

I. Why is the Fan Indispensable for Inverters?

During operation, inverters generate substantial heat, particularly in power components such as IGBTs, rectifier modules, filter inductors, and capacitors. The heat dissipation in these areas is significant.

Inadequate thermal management may lead to the following consequences:

• Overheating of control circuits → Malfunctions

• System temperature alarm → Automatic frequency reduction or shutdown

• Component failure → Direct burnout with high repair costs

Therefore, the Cooling Fan is not an optional accessory but a critical component ensuring the long-term stable operation of the inverter.

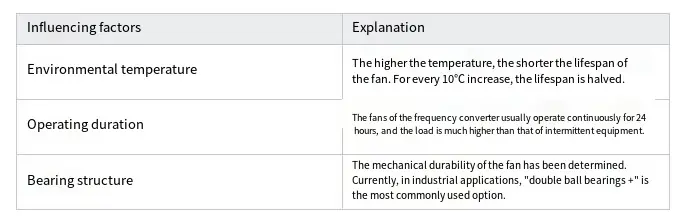

II. The Three Core Factors Influencing Fan Lifespan

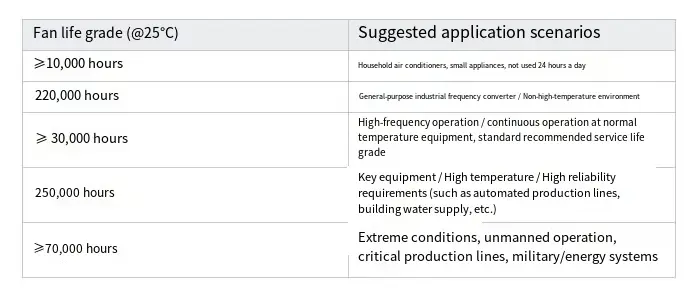

Under standard industrial inverter operating conditions, it is recommended that the fan lifespan should be no less than 30,000 hours (equivalent to approximately 3.4 years of continuous operation). The extended-life series of fans manufactured by Fuqingda can achieve a service life of up to 20.5 years.

III. How to Choose the Life Grade of the Fan for a Frequency Converter?

Caution: When ambient temperatures reach 40°C or higher, a significant reduction in operational lifespan may occur, necessitating the selection of higher-grade cooling fans or scheduled replacement intervals.

IV. Fan Lifespan ≠ Time to Failure, but Rather "Expected Operational Duration"

The lifespan of a fan refers to the L10 lifespan, which is the average number of hours that 90% of the fans can operate normally under specified conditions. For example, if a fan is labeled with a lifespan of 40,000 hours, it means that in a standard environment (25°C), 90% of the fans can run for 40,000 hours.

However, in actual field conditions with high temperatures, excessive dust, and heavy loads, the actual lifespan may decrease by 30% to 50%!

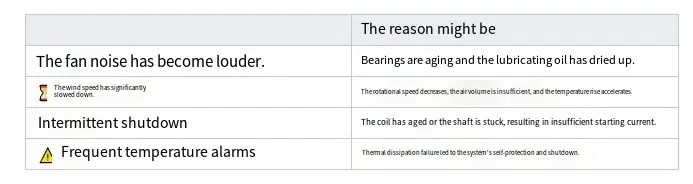

V. How to Determine Insufficient Fan Lifespan?

During inverter operation, the following indicators may suggest that the fan is approaching the end of its service life:

Recommendation: It is advisable to incorporate the fan as a component of routine maintenance, with a replacement interval of 2-3 years, to prevent minor issues from escalating into significant problems.

Conclusion:

Despite its compact size, the fan plays a pivotal role in system performance. While the inverter has been meticulously selected, has the fan been equally well-chosen? It is imperative to ensure that the fan does not become the system's weakest link.

Utilizing a fan with a limited lifespan is akin to equipping a Mercedes with tricycle tires—such a configuration not only compromises the vehicle's range but also significantly increases the risk of failure. Conversely, selecting a fan with an appropriate lifespan ensures stable operation for three, five, or even more years, thereby enhancing both reliability and safety.