What is the proper method for connecting only three out of the four wires of a cooling fan?

Introduction to the Functions of a Four-Wire Cooling Fan

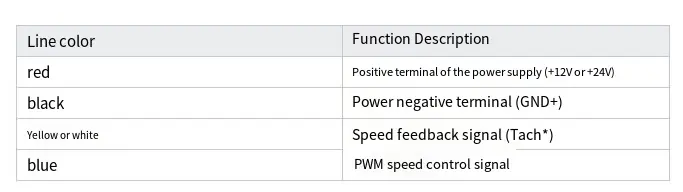

Four-wire fans typically comprise the following components:

Among these, the red and black wires provide the primary power supply to the fan, the yellow wire is utilized for speed sensing, and the blue wire serves for PWM signal-based speed control.

The four-wire fan is connected using only three wires.

The standard three-wire connection method involves the following steps:

- Connect the red wire to the positive power supply (+V).

- Connect the black wire to ground (GND).

- Connect the yellow or white wire for speed feedback.

In this configuration, the fan operates normally with power supply and supports speed feedback functionality. However, the PWM speed control line (blue) remains unconnected, causing the fan to typically run at full speed.

Examples of application scenarios:

- The rotational speed of the fan requires monitoring, but speed control is not necessary.

- The controller or device lacks a PWM speed regulation interface.

- It is necessary to simplify the circuit while still obtaining feedback on the operational status of the fan.

Precautions for the Three-Wire Connection Method:

1. Leave the PWM Speed Control Line Unconnected. When the PWM signal is not in use, the fan typically operates at full speed by default, which satisfies the cooling requirements of most users.

2. Ensure Proper Insulation of Signal Lines. The unconnected PWM lines must be adequately insulated to prevent potential interference.

3. Verify Correct Connection of the Speed Feedback Line. Ensure that the speed feedback line is connected to the appropriate interface on the control board to enable effective monitoring of the fan's operational status.

4. Match Power Supply Voltage with Rated Fan Voltage. Confirm that the supply voltage corresponds to the fan's rated voltage to avoid any risk of damaging the device.

Why is it not advisable to omit the rotational speed feedback line?

The speed feedback line serves as a critical signal for monitoring the operational health of the fan. Detecting fan stoppages or abnormal speeds in a timely manner can effectively prevent equipment overheating and associated malfunctions. In applications involving critical equipment, it is strongly recommended to maintain at least three connection lines.

Summary:

When a cooling fan has four wires but only three are required for operation, it is typically connected to the positive terminal of the power supply (red wire), the negative terminal (black wire), and the speed feedback wire (yellow/white wire). The PWM speed control wire (blue wire) is left unused. This configuration ensures the basic functionality of the fan while enabling monitoring of its rotational speed status, making it suitable for a wide range of industrial and electronic device applications.

If you have specific fan models or equipment requirements, please do not hesitate to contact Shenzhen Fuqingda Electronic Technology Co., Ltd. Our company provides professional services including fan selection, wiring guidance, and customization tailored to your needs.