What is the most accurate method for measuring air flow?

Why is air flow measurement so important?

Air flow is a core indicator for evaluating the performance of fans and ventilation systems. Inaccurate measurement may lead to the following problems:

❌ Lower than expected cooling performance: If the air flow is overestimated, it may not provide sufficient cooling effect in actual applications.

❌ Incorrect Fan selection: Inaccurate data may lead to the wrong fan selection, affecting the heat dissipation design of the product.

❌ Equipment overheating and shortened lifespan: Underestimating the air flow may result in insufficient heat dissipation of the equipment, shortening its lifespan.

✅ Therefore, precise measurement of air flow is crucial for ensuring the cooling effect of fans and the performance of equipment!

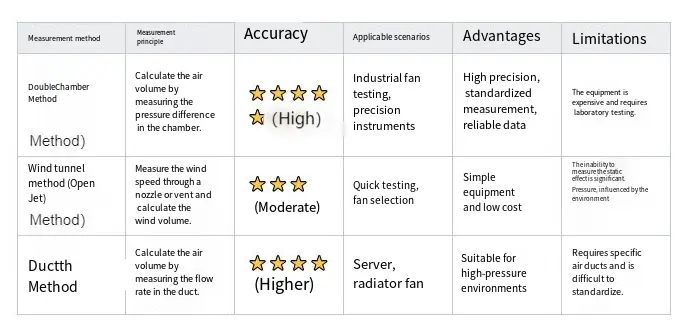

Comparison of the Three Mainstream Airflow Measurement Methods

The most commonly used airflow measurement methods currently mainly include the following three, each with its applicable scenarios and differences in accuracy:

1.Double Chamber Method: Laboratory-level High Precision Measurement

The Double Chamber Method is currently the most accurate measurement method and is recognized by the AMCA (Air Movement and Control Association) standard.

Measurement Principle •

Two chambers (Chamber A and Chamber B) are adopted, with the fan installed between the chambers. •

By adjusting the nozzle opening, the pressure difference (Pn) of the chamber is changed, and the air flow rate at different static pressures is measured. •

Calculation formula:

Q = 0.6 × A × V

Where: •

A: Nozzle cross-sectional area (m²). •

V: Wind speed (m/s), calculated as: V = √(2Pn/F) where Pn is the pressure difference and F is the air density.

✅The dual-chamber method has extremely high accuracy and is widely used in high-demand applications such as industrial fans and server fans. Applicable scenarios: •

Industrial fan testing •Precision laboratory measurement •

Equipment for high-precision air volume and static pressure testing

✅ Advantages

✔ High accuracy with minimal error

✔ Can measure air volume and static pressure simultaneously

✔ Test data is repeatable and conforms to international standards

❌ Limitations •

The equipment is expensive and requires a professional laboratory. •

The complex duct environment cannot be simulated.

2. Open Jet Method: Suitable for Rapid Airflow Volume Testing

The open jet method involves measuring the wind speed at the air outlet and calculating the airflow volume, making it suitable for rapid testing.

Measurement Principle •

Use a wind tunnel or nozzle and let the fan blow out air. •

The wind speed at the air outlet is measured by a wind speed sensor, and the air volume is calculated.

✅ Calculation formula:

Q=A×VQ = A \times VQ=A×V

Among them: •

A: Nozzle cross-sectional area (m²). •

V: Wind speed at the air inlet (m/s).

Applicable scenarios: •

Personal fan, consumer-grade Cooling Fan test •

Quick estimation of fan air volume •

Scenarios requiring low-cost and rapid measurement

✅ Advantages

✔ Simple equipment, low testing cost

✔ Fast measurement speed, suitable for selection comparison

❌ Limitations •

Static pressure cannot be measured. •

It is greatly influenced by the environment and has a relatively high error rate.

3. Duct Method: Applicable to Server and Heat Sink Fans

The duct method is suitable for fans that require high static pressure, such as server fans and heat sink fans.

Measurement Principle •

A closed air duct is adopted to allow the fan to drive the air flow. •

Multiple wind speed sensors are arranged in the air duct to measure the wind speed and calculate the air volume.

✅ Calculation formula:

Q=∑i(Ai×Vi)Q = \sum_{i} (A_i \times V_i)Q=i∑(Ai×Vi)

Among them: •

A_i: The area of each measurement point in the air duct. •

V_i: Wind speed at the measurement point.

Applicable scenarios: •

Server, radiator fan •

Fans that need to operate in a high static pressure environment •

Evaluating the actual performance of fans in air ducts

✅ Advantages

✔ Suitable for testing high static pressure fans

✔ Can simulate actual air duct environments

❌ Limitations •

Special air ducts are required. •

It is difficult to standardize, and the comparability of test data is relatively low.

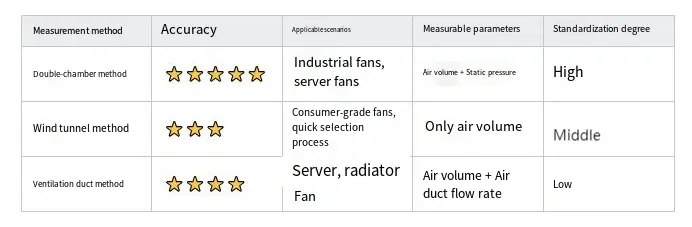

Which method is the most accurate? Here's the conclusion!

✅ If you aim for the highest precision, choose the dual-chamber method!

✅ If you need a quick test, the wind tunnel method is a good choice!

✅ If you want to test the actual performance of the fan in the air duct, the air duct method is the most suitable!

Summary and Comparison of Three Methods

✅ If precise measurement of the air flow of a fan is required, the dual-chamber method is the best choice!

✅ When purchasing a fan, it is recommended to refer to the data tested by the dual-chamber method to ensure the accuracy of the heat dissipation performance!