What factors contribute to the broader applicability of DC fans relative to AC fans?

Ac Fans operate on the principle of electromagnetic induction, utilizing the interaction between stator and rotor magnetic poles to drive fan blade rotation, thereby generating airflow and air pressure. These fans exhibit a fixed rotational speed characteristic, rendering speed control unattainable and precluding the integration of rotational speed monitoring capabilities. Typically powered by 220 V or 110 V AC supply, AC fans are often the preferred solution in systems where DC power is unavailable. However, due to their inherent inability to modulate speed, their application is considerably constrained in environments requiring high airflow performance.

DC fans function according to the operating principles of brushless motors. By employing Hall effect sensors to detect magnetic field variations, they enable precise commutation of the rotor's magnetic poles, thus driving the fan blades to rotate and produce airflow. This type of fan offers key advantages such as variable speed control, real-time speed monitoring, and signal feedback functionality, making it widely adopted in diverse electronic systems. Nevertheless, its dependency on a DC power source restricts deployment in applications lacking compatible power infrastructure. Aside from this constraint, DC fans demonstrate distinct advantages over AC fans in the following seven aspects:

1. High Efficiency and Energy Savings

• Working Principle: DC fans utilize DC motors and employ a combination of direct current voltage and pulse width modulation (PWM) signals for precise speed control, resulting in high energy conversion efficiency.

• Energy Consumption Comparison: When delivering equivalent airflow, DC fans exhibit significantly lower power consumption compared to AC fans. In applications requiring continuous operation and high energy efficiency—such as servers and telecommunications base stations—this translates into reduced electricity usage and lower operational costs.

• Environmental Benefits: The low-power operation of DC fans supports global initiatives for energy conservation and sustainability, and complies with increasingly stringent environmental regulations and energy efficiency standards.

2. Precise Speed Control and Intelligent Speed Regulation

• PWM/Voltage Control: DC fans enable stepless speed regulation by modulating the input voltage or accepting pulse width modulation (PWM) signals, offering high precision and excellent dynamic response characteristics.

• Temperature-Dependent Control: The thermal management circuit on the motherboard continuously monitors the device’s operating temperature in real time and dynamically adjusts fan speed accordingly. During low-temperature operation, the fan runs at reduced speed to minimize acoustic noise; under elevated temperatures, it increases rotational speed to ensure effective heat dissipation.

• Operational Benefits: This "on-demand cooling" intelligent control strategy eliminates unnecessary noise and energy consumption associated with continuous full-speed operation, achieving an optimal balance among thermal performance, acoustic comfort, and energy efficiency.

3. Extended Service Life and Enhanced Operational Reliability

• Brushless Motor Design:Modern DC Cooling Fans are predominantly equipped with brushless DC motors (BLDC), which eliminate mechanical brushes in their construction. This design inherently prevents spark generation, premature wear, and electromagnetic interference associated with traditional brushed motors, thereby significantly improving long-term reliability and system stability.

• Advanced Bearing Technology: These fans typically incorporate high-durability bearings—such as ball bearings or advanced fluid dynamic bearings—with a rated service life ranging from tens of thousands to over 100,000 hours. This enables reliable performance under continuous 7×24 operation, making them ideal for deployment in mission-critical applications including servers, telecommunications infrastructure, and industrial control systems.

4. Low Noise and Enhanced Operational Quietness

• Variable Speed Control: In typical operating conditions, fans maintain stable operation at medium to low rotational speeds, significantly reducing wind-induced aerodynamic noise and mechanical vibration emissions. This capability enables a substantially quieter acoustic environment, particularly in noise-sensitive applications.

• Brushless Motor Architecture: The use of brushless DC motors inherently eliminates electromagnetic interference and mechanical noise generated by brush-commutator friction, resulting in superior acoustic performance and long-term operational silence.

• Precision Manufacturing and Aerodynamic Design: Fan impellers are engineered with advanced aerodynamic profiling to minimize airflow turbulence and vortex formation, thereby reducing noise sources at the origin. This design ensures consistently low sound levels and improved acoustic characteristi

5. Extended Operating Voltage Range

• Wide Voltage Compatibility: DC fans are typically designed with standard rated voltages of 24V, 12V, and 5V; however, they often support an extended operational range from 3V to 30V. This wide input voltage tolerance enables stable performance despite fluctuations in power supply, thereby improving power source compatibility and system flexibility. As a result, these fans are well-suited for deployment across diverse electrical environments and electronic systems with varying voltage requirements.

6. Reduced Electromagnetic Interference (EMI)

• Superior Electromagnetic Compatibility of Brushless Motors: Compared to brushed motors and certain types of AC motors, brushless DC motors exhibit significantly lower electromagnetic interference during operation. This reduction is attributed to the absence of mechanical commutation, which eliminates high-frequency noise emissions caused by intermittent electrical contact switching. As a result, brushless fans demonstrate enhanced electromagnetic compatibility, making them particularly suitable for use in environments with stringent EMI requirements. They are ideally deployed in sensitive electronic systems—such as audio processing equipment and precision measurement instruments—where they help maintain the stable and reliable performance of adjacent circuits and critical components.

7. Compact Form Factor and Enhanced Integrability

• Space-Efficient Structural Design: DC fans are engineered with a compact and low-profile configuration, offering high spatial efficiency. This design enables seamless integration into modern electronic systems where miniaturization is a key requirement. Widely deployed in space-constrained applications such as laptops, graphics cards, mini desktops, and network routers, these fans contribute to improved system-level integration density and overall design flexibility.

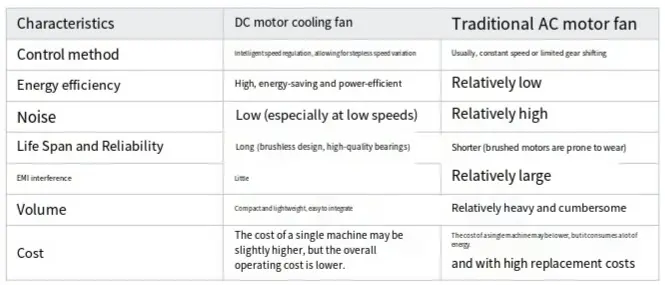

Comparative Analysis Between DC and AC Motor Fans

Application Scenarios

Owing to their comprehensive advantages in energy efficiency, noise suppression, speed regulation capability, and compact design, DC motor cooling fans have become the predominant thermal management solution across the following key application domains:

• Computing Systems: Widely integrated into CPU coolers, graphics card cooling modules, chassis ventilation fans, and power supply units, ensuring effective heat dissipation in high-performance computing environments.

• Communication Infrastructure: Routinely deployed in servers, network switches, routers, and base station equipment, where they maintain thermal stability during sustained high-load operations.

• Consumer Electronics: Employed in high-performance devices such as gaming consoles, smart televisions, and projectors, addressing continuous thermal demands associated with prolonged usage.

• Industrial Automation: Utilized in variable frequency drives, servo drives, and industrial control cabinets, serving applications that require high reliability and resilience under challenging environmental conditions.

• Automotive Electronics: Applied in thermal management systems for automotive infotainment units and LED headlights, enabling stable performance of onboard electronic components under diverse and complex operating conditions.

In summary, DC motor cooling fans have emerged as the dominant solution in the active thermal management market for modern electronic equipment, driven by their core advantages in energy efficiency, low-noise operation, intelligent speed regulation, and extended service life. These performance attributes position them as the preferred choice under the dual forces of technological advancement and evolving market demands.

Shenzhen Fuqingda Electronic Technology Co., Ltd. offers a comprehensive portfolio of AC and DC cooling fans, delivering efficient and reliable thermal management support across diverse application environments. As a trusted partner in thermal solution development, we welcome inquiries from prospective clients and look forward to establishing collaborative partnerships.