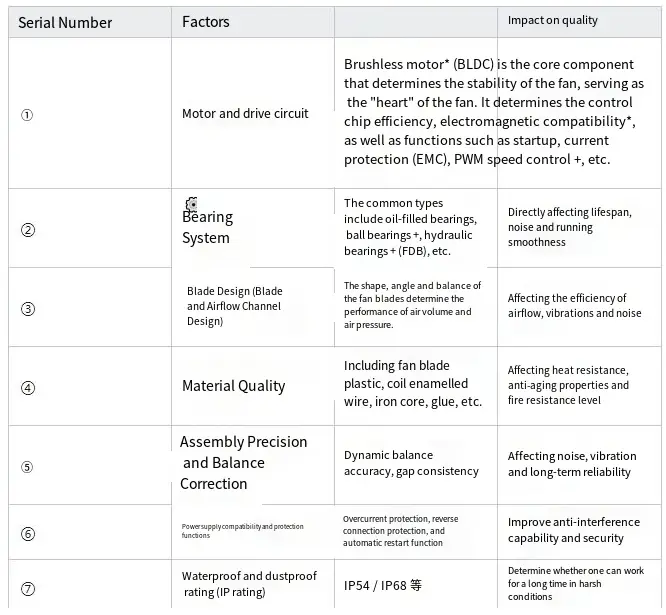

What are the key factors affecting the quality of cooling fans?

1. Key Factors Affecting the Quality of Heat Dissipation Fans

2. Detailed Explanation of Key Components

1️⃣ Motor and Drive Circuit •

High-quality fans are equipped with high-efficiency brushless DC motors (BLDC). •

Equipped with a dedicated driver IC, it can achieve PWM speed regulation, FG signal feedback, and soft start. •

It is equipped with overvoltage and locked-rotor protection to prevent burning out. •

Magnetic circuit optimization can reduce the starting current and improve efficiency.

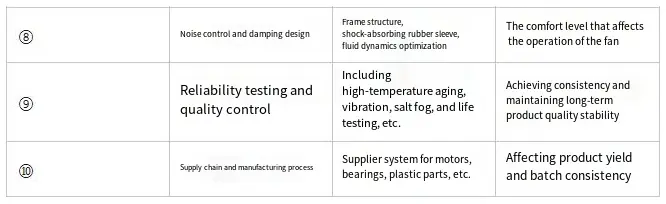

2️⃣ Bearing System

High-quality fans typically employ ball or hydraulic bearings, enabling long-term stable operation in environments exceeding 70°C.

3️⃣ Blade Design and Dynamic Balance •

The optimized blade angle and streamlined design can enhance the efficiency of air flow. •

Dynamic balance testing is a crucial process. Poor balance can lead to: •

The noise level is too high. •

Increased vibration; •

The bearing wears out prematurely.

4️⃣ Materials and Structure •

The materials for fan blades and frames are mostly PBT + 30% glass fiber or UL94V-0 flame-retardant materials. ;

•

High-temperature type uses heat-resistant enameled wire. •

The materials such as glue and shaft cores must be able to withstand temperatures above 100°C without deformation.

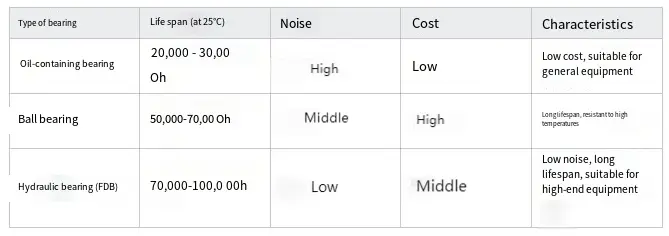

5️⃣ Reliability and Quality Verification

High-quality fans must pass strict tests before leaving the factory:

3. Summary Comparison Table

4. Conclusion

A high-quality Cooling Fan is not merely about "spinning fast", but about "spinning steadily for a long time", maintaining reliable cooling in any environment. A truly good fan must balance: •

Performance (Airflow and Air Pressure) •

Reliability (Life and Protection) •

Consistency (Batch Stability) •

Experience (low noise and smooth operation)