Understanding fan types is essential for achieving precise thermal management—A classification of cooling fans

First Dimension: Classification by Airflow Principle and Structural Design

This classification represents the most fundamental and essential approach for Cooling Fans, as it directly determines their operational behavior and aerodynamic performance.

1,Axial-Flow Fan – A General-Purpose Air Movement Solution

Working Principle: Blades rotate about a central axis, generating airflow that moves parallel to the axis of rotation. This mechanism is analogous to that of conventional household fans.

Key Characteristics: High volumetric airflow, strong cost-effectiveness, and the widest range of applications among fan types.

Advantages: Mature technology, high operational efficiency, comprehensive product availability, and flexibility in selection and integration.

Limitations: Relatively low static pressure output, resulting in limited effectiveness when attempting to force air through densely packed or thick thermal obstacles. Best suited for applications with minimal resistance to airflow.

Typical Applications:

- Internal ventilation and cooling in desktop computer enclosures

- Forced-air cooling systems in electronic equipment cabinets (e.g., network switches, server racks)

- Air circulation subsystems in consumer appliances (e.g., air purifiers, projectors)

2. Centrifugal Fan – A High-Pressure Airflow Solution

Working Principle: As the impeller rotates at high speed, air is drawn in through an inlet positioned perpendicular to the rotational axis and is expelled radially outward toward the outlet under centrifugal force, resulting in a 90° deflection of the airflow direction.

Key Characteristics: Delivers high static pressure, exhibits concentrated airflow distribution, and features a compact design, making it well-suited for confined installation spaces.

Advantages: Particularly effective in applications involving high flow resistance or complex thermal pathways. Capable of overcoming significant system impedance and enabling directed airflow delivery.

Limitations: Generates relatively higher operational noise; for a given footprint, its volumetric airflow capacity is typically lower than that of axial-flow fans.

Typical Applications:

- Internal cooling modules in notebook computers

- Dedicated thermal management systems for graphics cards (designed to expel heat directly through the side panel of the chassis)

- Ventilation and heat exchange systems in automotive air conditioning units

- Industrial blowing equipment (e.g., high-temperature hot air guns, blow-suction machines)

3. Mixed-Flow Fan – A Balanced Airflow Solution

Working Principle: Combining the aerodynamic characteristics of both axial-flow and centrifugal fans, the mixed-flow fan directs air diagonally through the impeller, enabling a hybrid flow pattern that incorporates axial intake and radial discharge.

Key Characteristics: Delivers high volumetric airflow and moderate static pressure simultaneously, offering well-balanced aerodynamic performance.

Advantages: Achieves an optimal compromise between airflow capacity and pressure generation, while maintaining favorable noise levels. This makes it suitable for applications requiring both effective thermal management and acoustic comfort.

Limitations: More complex in design and manufacturing compared to conventional fan types, resulting in higher production costs and reduced cost-effectiveness in budget-sensitive applications.

Typical Applications:

- High-performance computing hardware (e.g., premium CPU coolers, silent desktop systems) where both efficient heat dissipation and low operational noise are critical

- Computer chassis ventilation systems requiring substantial airflow delivery under moderate flow resistance

- Precision air conditioning units in server rooms and data centers, used for stable, efficient, and quiet environmental temperature control

Second Dimension: Classification by Bearing Technology

The bearing serves as the core component of a fan, directly influencing its service life, operational noise, and overall reliability.

1. Sleeve Bearing

Working Principle: Lubricating oil forms a protective film between the rotating shaft and sleeve, reducing frictional resistance and enabling smooth rotational operation.

Advantages: Features extremely low manufacturing costs and low acoustic emissions during initial operation, with favorable startup quietness.

Limitations: Limited service life due to the gradual evaporation or degradation of lubricant over time; susceptibility to dust contamination further accelerates wear and leads to significantly increased noise in later operational stages. Additionally, poor thermal stability results in performance deterioration under high-temperature conditions.

Application Scope: Primarily used in cost-sensitive consumer electronic devices with relatively short intended service periods.

2. Hydraulic Bearing

Working Principle: An enhanced variant of the oil-filled bearing design, incorporating optimized internal oil-channel geometry and improved sealing technology to effectively suppress lubricant evaporation and contamination, thereby enhancing long-term operational stability.

Advantages: Offers substantially improved service life and reliability compared to conventional oil-filled bearings, while maintaining consistently low noise levels. Combines effective acoustic performance with high cost-efficiency.

Limitations: Durability and dynamic load-handling capability remain inferior to advanced bearing technologies—such as magnetic levitation and dual ball bearings—under extreme operating conditions.

Application Scope: Widely adopted in mainstream PC cooling fans and represents the dominant technical solution in the mid-tier market segment.

3. Ball Bearing

Working Principle: Employs a set of precision metal balls to convert sliding friction between the shaft and sleeve into rolling friction, thereby significantly reducing mechanical wear and enhancing rotational efficiency.

Advantages: Offers an exceptionally long service life, excellent thermal resistance, and high operational stability, ensuring reliable performance under continuous operation and high-load conditions.

Limitations: Higher manufacturing cost due to complex assembly; may generate slight rolling element noise (commonly referred to as "ball bearing rumble") at low rotational speeds, which can be perceptible in acoustically sensitive environments.

Application Scope: Commonly deployed in industrial machinery, server systems, and other mission-critical applications requiring 24/7 continuous operation with high durability and reliability.

4. Magnetic Levitation Bearings / Fluid Dynamic Bearings

Working Principle: Utilizes electromagnetic forces or hydrodynamic oil film pressure to suspend the rotating shaft core without physical contact against the bearing surface, minimizing mechanical friction and wear.

Advantages: Delivers ultra-long service life, extremely low acoustic emissions, and superior vibration damping characteristics. Represents the most advanced bearing technology currently available for consumer-grade cooling fans.

Limitations: Highest production cost among common Fan Bearing types, primarily attributed to sophisticated materials and precision manufacturing requirements.

Application Scope: Ideal for high-performance PC cooling solutions, HTPC (Home Theater PC) systems, and professional environments—such as content creation studios, recording facilities, and quiet office spaces—where minimal noise and stable operation are critical.

Third Dimension: Classification by Special Functions and Characteristics

Modern fans have evolved into specialized technical variants designed to fulfill specific functional requirements, addressing the diverse demands of various application environments.

1. PWM Intelligent Temperature-Controlled Fan

Key Features: Supports PWM (Pulse Width Modulation) signal input, enabling precise stepless speed control across a wide operating range (e.g., 20%–100%) based on real-time CPU or system temperature feedback. Offers high regulation accuracy and rapid dynamic response.

Advantages: Ensures quiet operation during low-load conditions while delivering robust cooling performance under high thermal loads, effectively balancing energy efficiency, acoustic noise, and thermal management effectiveness.

2. RGB/ARGB Lighting Fan

Key Features: Equipped with high-density LED arrays capable of producing static single-color illumination and programmable dynamic lighting effects—including breathing, color cycling, wave patterns, and audio synchronization. Many models support mainstream motherboard lighting synchronization technologies such as ASUS Aura Sync, MSI Mystic Light, GIGABYTE RGB Fusion, and ASRock Polychrome Sync.

Advantages: Integrates functional heat dissipation with customizable aesthetic design, making it ideal for enthusiast-grade DIY desktop builds and showcase systems where visual appeal is a key consideration.

3. Waterproof and Dustproof Fan

Key Features: Designed with an enclosed sealing structure, compliant with international ingress protection standards (IP Code), commonly rated at IP55 or IP68 levels, providing reliable resistance against dust ingress and water splashing or immersion.

Advantages: Suitable for deployment in challenging environments such as outdoor installations, humid areas, industrial facilities, and high-particulate workspaces, ensuring stable and durable operation under adverse conditions.

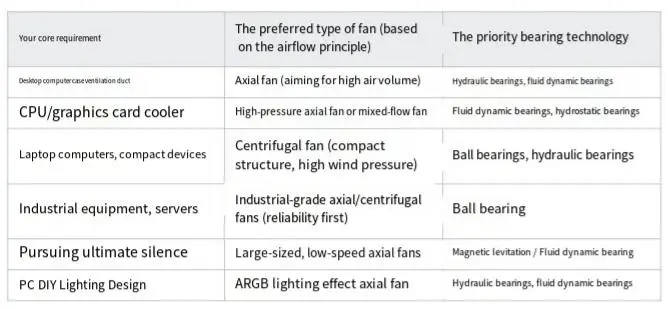

Summary: Fan Selection Guidelines Based on the Classification Framework

Conclusion:

A comprehensive understanding of the classification system for cooling fans serves as a systematic and reliable selection framework. Whether deployed in personal computers, server systems, or household appliances, appropriate fan models can be accurately identified through a structured evaluation process based on three key dimensions: airflow characteristics, bearing technology, and specialized functional features. By following a methodical decision-making approach, engineers and designers can effectively integrate efficiency, operational reliability, and low acoustic noise into a cohesive thermal management solution, ensuring that cooling systems are precisely aligned with application requirements and deliver optimal performance under real-world operating conditions.

Shenzhen Fuqingda Electronics Technology Co., Ltd. has over 20 years of experience in thermal management R&D and manufacturing, offering a comprehensive range of product specifications suitable for diverse application scenarios. Should you have any requirements regarding cooling solutions, we welcome your inquiry at any time.