Is the AC cooling fan still worth recommending in industrial scenarios?

Before delving into the selection of Cooling Fans, it is essential to first establish a fundamental premise: there are significant differences between industrial application scenarios and consumer-grade devices.

The core concern of industrial equipment is not merely "whether the performance is sufficient", but rather the reliability of the system operation, especially the avoidance of "unexpected failures". The typical characteristics of the industrial environment are as follows: it needs to operate continuously 24/7; the working environment has a high temperature and limited cooling conditions; power fluctuations are more frequent than in laboratory environments; and the maintenance cost of the equipment is significantly higher than the purchase cost of the components themselves.

In this context, the selection logic for cooling fans differs fundamentally from that in the consumer electronics sector - their design priorities are more focused on long-term stability, environmental adaptability and maintainability, rather than extreme performance or complex functionality.

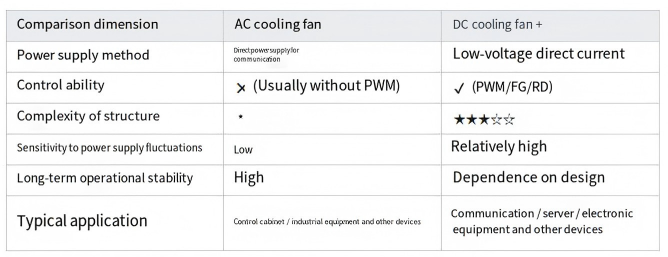

AC cooling fan vs DC cooling fan: Core Difference Comparison

The conclusion is quite clear:

DC cooling fans have greater advantages in terms of control flexibility and functional integration, and are suitable for application scenarios that have high requirements for speed regulation accuracy and intelligent management; while AC cooling fans are renowned for their simple structure, stable operation, and high durability, and demonstrate higher reliability in complex industrial environments. Therefore, in the actual selection of industrial sites, AC cooling fans are often preferred to meet the strict requirements for long-term stable operation and low maintenance.

Among various industrial projects, AC (alternating current) cooling fans are still widely recommended for use. From the perspective of engineering selection, there are several practical technical and system-level reasons behind this:

- It can directly connect to the AC power supply, simplifying the system design and reducing the integration complexity;

- It does not rely on additional control circuits such as PWM drivers or voltage stabilizing modules, reducing the number of fault nodes;

- It has strong adaptability to grid voltage fluctuations and performs more stably in applications with unstable power quality;

- The failure rate is low during long-term operation, and it has higher operational reliability;

- The service life is stable, the replacement cycle is predictable, and it is conducive to formulating preventive maintenance plans.

For industrial system engineers, the "predictability" of a system is often more of an engineering value than mere "high performance", as it directly affects the availability of equipment, operational efficiency, and the control of the overall lifecycle cost.