How to Select the Salt Spray Protection Level for a Cooling Fan?

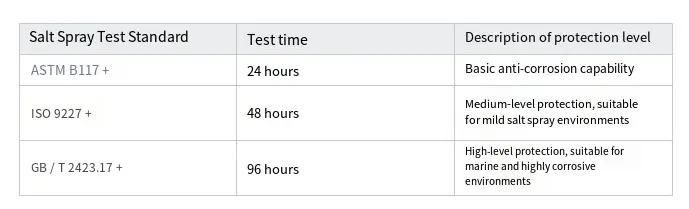

Introduction to Salt Spray Protection Grades:

The salt spray protection level is typically determined through the salt spray test (Salt Spray Test), which is utilized to assess and evaluate the corrosion resistance of both the external surface and internal structure of a device in a salt spray environment. Common standards encompass the following:

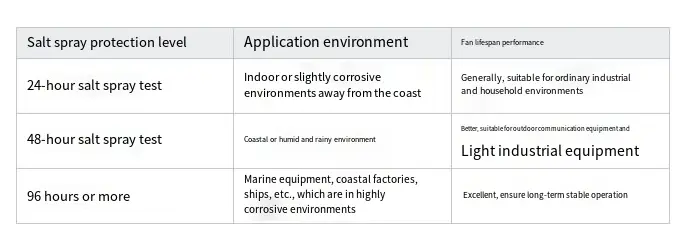

Application Scenarios Associated with Various Salt Spray Protection Ratings

How to Select the Appropriate Salt Spray Protection Level?

1. Assess the Corrosion Intensity of the Working Environment

- Coastal Areas: It is highly recommended to select Fans with a salt spray protection rating of ≥48 hours.

- Industrial Pollution Areas: Choose medium to high levels of protection based on specific environmental corrosion factors.

- Indoor Dry Environments: A low level of salt spray protection is sufficient.

2. Consider the Importance of Equipment and Maintenance Cycles

- For critical equipment or systems that are difficult to maintain frequently, priority should be given to high-grade salt spray protection products.

- For short-term use or easily maintainable equipment, the salt spray protection level can be appropriately reduced.

3. Balance Cost and Performance Comprehensively

The cost of high-grade salt spray protection materials and processes is relatively high. Therefore, they should be reasonably selected based on the project budget and risk tolerance.

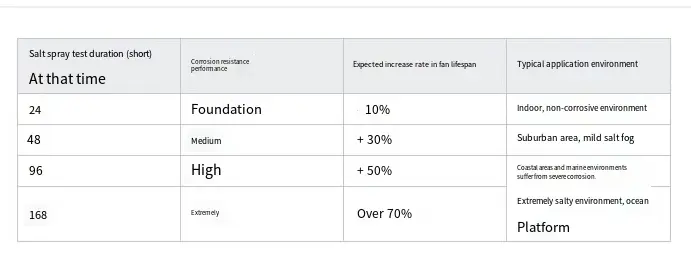

Schematic Table Illustrating the Relationship Between Salt Spray Protection Levels and Fan Lifespan

Conclusion:

Selecting the appropriate salt spray protection level is crucial for ensuring the long-term stable operation of cooling fansin corrosive environments. Shenzhen Fuqingda Electronic Technology Co., Ltd. provides a diverse range of Cooling Fans to address varying salt spray protection requirements, thereby guaranteeing the safety and reliability of your equipment.