How to Select the Optimal Cooling Fan for LED Lamps?

1. Evaluate the Power and Heat Output of LED Lamps

The heat generated by LED lamps varies depending on their power during operation. Higher-power LED lamps produce more heat, thereby increasing the demand for effective heat dissipation. Consequently, when selecting a Cooling Fan, it is essential to first assess the power rating of the LED lamp and its corresponding heat output. Typically, high-power LED lamps require a substantial air-cooling fan to ensure that the generated heat is promptly dissipated, maintaining the lamp's optimal operating temperature. For low-power LED lamps, a cooling fan with a relatively smaller airflow capacity can be chosen to minimize energy waste and reduce noise interference.

2. Assess the Temperature and Humidity of the Working Environment

The working environment significantly influences the heat dissipation requirements of LED lamps. In environments characterized by high temperatures and humidity, the need for efficient heat dissipation becomes more critical. Therefore, evaluating the temperature and humidity levels of the working environment is vital for selecting an appropriate cooling fan.

In high-temperature conditions, it is imperative to choose a cooling fan with robust high-temperature resistance. The fan's material should be capable of withstanding elevated temperatures while ensuring stable long-term operation. Additionally, the fan's design must accommodate high-temperature environments to prevent failures or potential damage to the LED lamp caused by overheating.

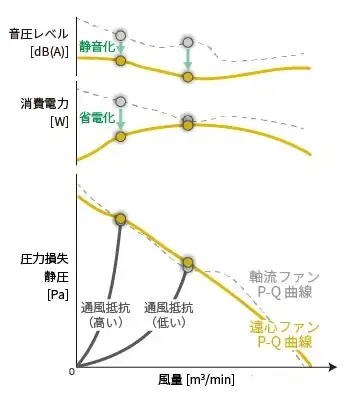

3. Balancing Airflow (CFM) and Noise Levels

Airflow is one of the most critical parameters when selecting a cooling fan, typically measured in CFM (cubic feet per minute). Adequate airflow ensures that the heat generated by the LED lamp is efficiently dissipated, maintaining the lamp's operating temperature within a safe range. However, higher airflow levels are often accompanied by increased noise, which may pose challenges in environments requiring quiet operation, such as homes or offices. Therefore, it is essential to strike an optimal balance between airflow and noise levels. An ideal cooling fan should provide sufficient thermal management while maintaining low acoustic emissions.

4. Material Selection and Durability Considerations

The material composition of a cooling fan significantly influences its thermal efficiency and durability. Common materials used in cooling fans include plastic and metal. Metal Fans, particularly those made from aluminum alloys, generally exhibit superior thermal conductivity and longer service life. In contrast, plastic fans, while lighter in weight, tend to have inferior heat dissipation capabilities. When selecting acooling fan, the choice of material should align with the specific working conditions of the LED lamp. For applications involving high-temperature environments, metal fans are preferable due to their enhanced heat dissipation and resistance to elevated temperatures. Although plastic fans offer cost advantages and reduced weight, they compromise on thermal performance and long-term reliability.

Efficient cooling fans not only effectively reduce the temperature of LED lamps but also significantly decrease energy consumption. When selecting a fan, it is crucial to consider its energy efficiency rating. Energy-efficient cooling fans provide enhanced cooling performance while consuming less power, thereby minimizing energy waste. Many modern cooling fans feature an optimized design that combines low power consumption with high efficiency, enabling them to meet heat dissipation requirements while reducing energy usage. Consequently, choosing a high-efficiency cooling fan can improve the thermal management of LED lamps, conserve energy, and lower electricity costs.