How to Select Axial Flow Fans, Centrifugal Fans, and Blowers?

II. Structure and Principles of Three Types of Fans

1. Axial Fan

• Structural Characteristics: The fan blades are parallel to the shaft ↔️, and the direction of airflow is consistent with the shaft.

• Working Principle: Similar to a propeller ️, it propels airflow along the axial direction.

• Typical Parameters: Airflow rate 1000-10,000 ㎥/h, static pressure 20-150 Pa, noise level 25~50 dB(A).

• Advantages ✔️: Compact size, high airflow rate, high efficiency ⚡, low noise level.

• Disadvantages ✖️: Relatively low static pressure (<150 Pa), not suitable for long ducts or high-resistance air delivery systems.

2. Centrifugal Fan

•

Structural Characteristics: Air enters the center of the impeller ⚪, is expelled through the blades, and undergoes a directional change (90°).

•

Operating Principle: Utilizes centrifugal force ∑F=mv²/r to pressurize air and alter its direction.

•

Typical Parameters: Airflow 500–8000 m³/h, static pressure 150–800 Pa, noise level 40–70 dB(A).

•

Advantages ✔️: High static pressure, suitable for long-distance or complex duct systems.

•

Disadvantages ✖️: Large size, complex structure ⚙️, relatively higher noise levels.II. Structure and Principles of Three Types of Fans

3. Blower

• Structural Characteristics: Available in centrifugal or cross-flow configurations, capable of generating extremely high air pressure (>1000 Pa).

• Operating Principle: Utilizes high-speed impellers/turbines to compress air and create concentrated airflow.

• Typical Parameters: Airflow capacity 300-5000 m³/h, air pressure 1000-5000 Pa, noise level 60-85 dB(A).

• Advantages ✔️: Exceptional air pressure, extended air delivery distance.

• Disadvantages ✖️: High energy consumption ⚡, elevated costs, significant noise levels.

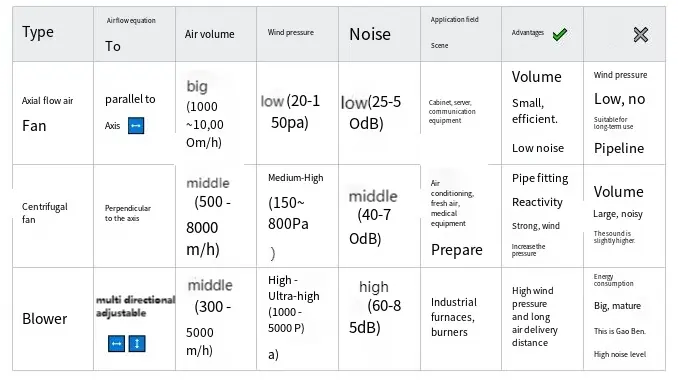

III. Performance Comparison Table

IV. Typical Application Scenarios

1. Telecommunications Industry

• Recommended: Axial Flow Fans

• Rationale: Base station cabinets feature short duct lengths, necessitating high airflow volume with low noise levels, while requiring minimal static pressure.

2. Medical Industry

• Recommended: Centrifugal Fans

• Rationale: Medical equipment incorporates complex internal air channels, requiring stable medium-to-high static pressure for optimal performance.

3. Industrial Production

• Recommended: Blowers / Large-scale Centrifugal Fans

• Rationale: These applications demand long-distance, high-pressure air delivery, particularly for combustion support and pneumatic conveying systems.

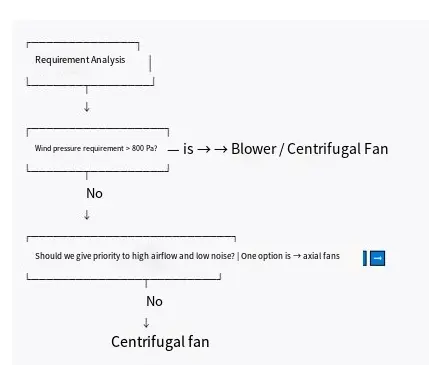

V. Equipment Selection Flowchart

VI. Key Considerations for Product Selection ⚠️

1. Operating Ambient Temperature ️: High-temperature environments (>80℃) require high-temperature resistant fans, such as the High-Temperature Series by Fuqingda.

2. Noise Level Requirements: Office/medical environments necessitate fans with noise levels ≤40 dB(A).

3. Lifespan: Ball Bearing fans offer extended longevity, while Sleeve Bearing fans provide cost-effective solutions.

4. Protection Rating ️: Outdoor/humid environments require a minimum IP55 rating.

5. Certifications: International certifications such as UL, CE, and RoHS ensure smooth export compliance.

VII. Conclusion

• Short-distance + High Airflow → Axial Flow Fan ⬅️➡️

• Medium-distance + Complex Ductwork → Centrifugal Fan ↗️↘️

• High Pressure + Long-distance → Blower

✅ Selecting the appropriate fan ≈ Enhanced Equipment Efficiency + Prolonged Service Life + Reduced Energy Consumption.

For professional selection and quotation services, please contact Shenzhen Fuqingda Electronics Technology Co., Ltd. We will customize the optimal solution for your specific requirements!