High-Performance Industrial-Grade Cooling Fan – Model 8025

Core parameters establish the foundation for superior performance.

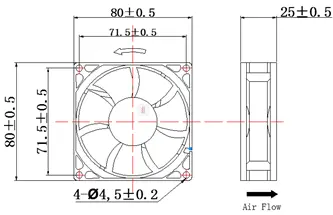

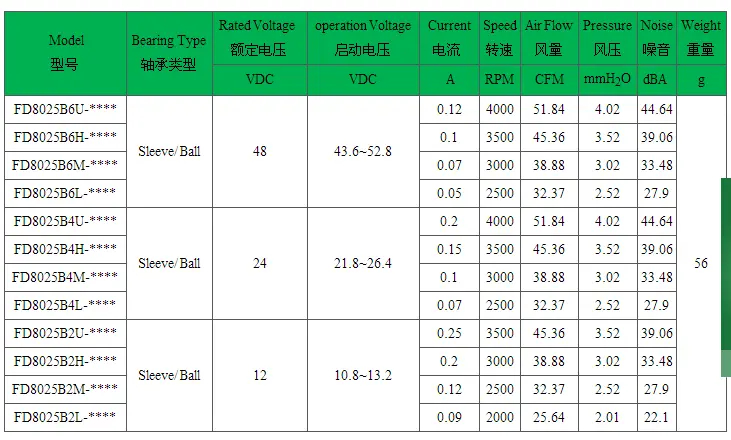

The FQD 8025 DC cooling fanhas standard dimensions of 80 × 80 × 25 mm, classifying it as an 8 cm Axial Fan. It supports three commonly used voltage ratings—12 V, 24 V, and 48 V—ensuring compatibility across a wide range of applications with varying power requirements.

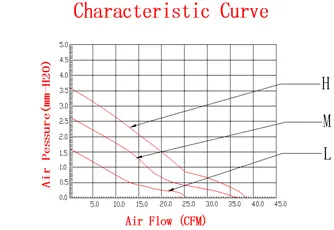

Key performance specifications include a variable rotational speed ranging from 3,000 to 6,000 RPM, delivering an airflow output of 39.67–76.87 CFM and a static pressure range of 3.80–14.29 mmAq. These characteristics enable rapid formation of efficient air circulation, significantly improving thermal dissipation in equipment. In addition, the fan demonstrates excellent noise control, with operational noise levels maintained between 32.2 and 48.6 dBA, achieving an optimal balance between high cooling performance and quiet operation.

The fan incorporates a fifth-generation upgraded DC brushless external rotor motor, paired with a frame and impeller constructed from PBT material. This combination ensures environmental friendliness, flame retardancy, low airflow resistance, high structural strength, and excellent mechanical toughness. The design is also resistant to vibration and embrittlement, making it suitable for demanding industrial environments. The bearing system features a high-precision dual ball bearing configuration, which enhances operational stability and significantly extends service life. With a total weight of only 65 g, the unit’s lightweight construction minimizes additional load on host equipment.

Meticulously engineered to balance high performance with environmental sustainability,

The FQD 8025 DC Cooling Fan exemplifies advanced design and functional efficiency. The fan embodies precision engineering in both material selection and structural configuration. Its motor coil is constructed from high-conductivity pure copper, which not only enhances electrical stability but also significantly reduces power consumption. This design meets stringent energy-saving and eco-friendly requirements, aligning with the global trend toward green and sustainable industrial development.

The PBT-based frame and impeller are optimized with a low-air-resistance aerodynamic structure, substantially improving airflow efficiency. Additionally, the inherent properties of PBT—such as excellent thermal resistance, anti-aging performance, and high mechanical strength—ensure long-term dimensional stability and sustained operational performance without deformation or degradation. The integrated dual ball bearing system serves as a critical component for longevity, delivering enhanced rotational stability and extended service life under continuous operation.

Designed for versatility, the fan operates reliably across a wide temperature range of –10 °C to +70 °C. It maintains stable performance in challenging environments, including cold outdoor installations and high-temperature enclosed equipment enclosures, making it highly adaptable to diverse geographical regions and complex application scenarios.

Integrated multifunctionality ensures enhanced safety and operational reliability.

The cooling fan incorporates a suite of advanced features designed to improve system safety, control precision, and application flexibility. It is equipped with PWM-based intelligent speed control, supporting precise frequency regulation from 100 Hz to 30 kHz. By dynamically adjusting rotational speed in response to real-time temperature changes, the fan enables demand-driven cooling performance, ensuring optimal thermal management while minimizing energy consumption.

For comprehensive protection, the device includes reverse polarity protection to prevent damage caused by incorrect wiring connections. The soft-start function mitigates inrush current during startup, thereby safeguarding both the motor and connected electronic components. A standard stall protection mechanism is implemented, along with integrated operational status monitoring and fault alarm capabilities. These functions allow continuous real-time assessment of fan performance and enable immediate alert signaling upon detection of anomalies, facilitating rapid diagnosis and maintenance intervention. Furthermore, the fan exhibits a defined level of water resistance, meeting requirements for reliable operation in humid environments and select outdoor installations, thus broadening its applicability across diverse industrial and environmental conditions.

Widely adaptable and engineered to support diverse industrial applications

The FQD 8025 DC cooling fan demonstrates exceptional environmental adaptability and operational reliability, making it a trusted thermal solution across multiple industrial sectors. In the new energy sector, it is deployed in critical systems such as energy storage units, photovoltaic inverters, and frequency converters, where it delivers efficient heat dissipation for high-power electronic components, thereby ensuring stable and efficient energy conversion processes. In the electronics industry, the fan is widely utilized in power modules, enclosures, security surveillance systems, video processing terminals, and related equipment, effectively mitigating thermal management challenges associated with prolonged continuous operation. Its robust design and consistent performance contribute to enhanced system stability and extended service life in demanding applications.