Do bearings significantly impact the service life of cooling fans?

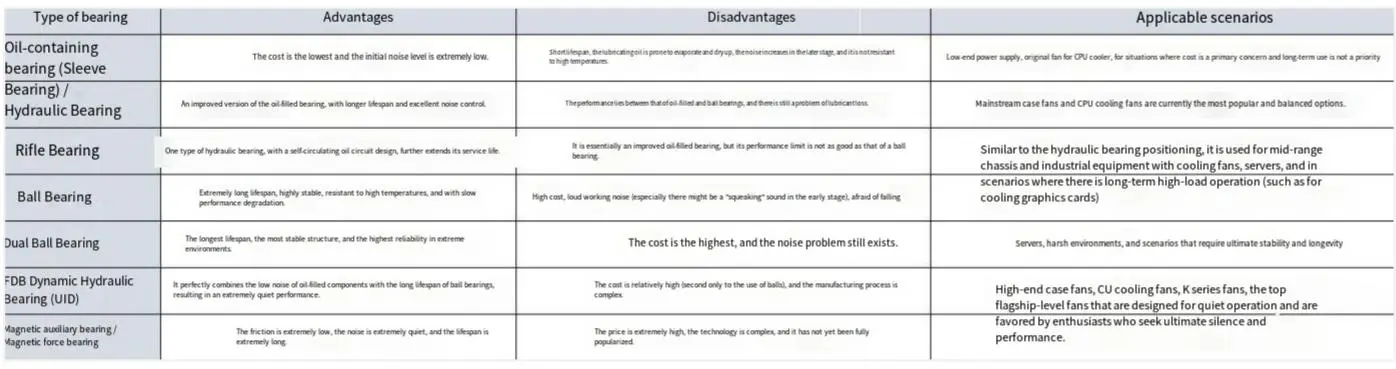

Before answering the above questions, it is necessary to first understand the common types of bearings in Cooling Fans.

Upon understanding the characteristics of various bearing types, an appropriate selection can be made by considering three key factors: application scenarios, budget constraints, and specific operational requirements.

1. Pursuing optimal acoustic performance and superior quality (for high-end applications):

Preferred solution: FDB dynamic hydraulic bearing.

This bearing type is widely recognized as the "King of Silence" in the consumer market, offering an exceptionally long service life and minimal operating noise. It has become the standard choice for high-end air-cooled heat sinks and chassis fans.

Alternative solution: High-quality hydraulic or sleeve bearing.

Numerous mid-tier products from reputable manufacturers incorporate this bearing type, delivering strong performance in noise reduction and durability, fully satisfying operational requirements in residential and typical office environments.

2. Pursuing a balance between cost-effectiveness and performance (mainstream application choice):

Preferred option: Hydraulic Bearing or Rifle Bearing.

These types of bearings are the most common and widely used in the current market, offering a reasonable cost, good noise reduction performance, and a lifespan sufficient to meet the needs of the majority of users for 3 to 5 years. For general users, choosing products with these types of bearings can ensure reliable and stable performance in most application scenarios.

3. Pursuing an extremely long service life and operational stability (applicable to special application scenarios):

Preferred solution: Dual Ball Bearing.

For devices that need to support continuous 7×24-hour operation (such as home servers, NAS systems), or for use in high-temperature chassis environments, dual ball bearings are the optimal choice due to their outstanding durability and reliability.

4. Extremely constrained budget (entry-level application scenario):

Preferred type: Sleeve Bearing.

This bearing type is widely employed in low-end products and original equipment manufacturer (OEM) fans for branded computers, offering a cost-effective solution despite its relatively limited service life. Users should anticipate a typical operational lifespan of one to two years and plan for timely replacement accordingly. However, their operational noise is relatively high, and they should only be selected if the noise level is acceptable.

To sum up, the following principles can be used for selection before purchase:

- Avoid choosing outdated oil-containing bearings in terms of technology;

- If cost performance is pursued, hydraulic bearings are recommended as the first choice, offering a good balance between performance and cost;

- For achieving better noise reduction, it is advisable to increase investment and prioritize FDB dynamic hydraulic bearings;

- For applications requiring high durability and where higher operating noise is acceptable, double ball bearings are the ideal choice.

Optimized text:

Shenzhen Fuqingda Electronic Technology Co., Ltd. specializes in the research, development, and manufacturing of a wide range of cooling fans. Our products are widely applicable across diverse operating environments and effectively meet varied customer requirements. We sincerely look forward to connecting with you to discuss potential collaboration opportunities.