News

What is the typical lifespan specification for the cooling fan in a frequency converter?

In electrical automation systems, the Variable Frequency Drive (VFD) serves as a critical component, extensively utilized in industrial control, air conditioning systems, machine tools, elevators, water pumps, and other equipment. However, it is noteworthy that over 30% of VFD malfunctions are attributed to the expiration of Fan lifespan without timely replacement.

This raises two pivotal questions:

What should be the standard lifespan of a VFD Cooling Fan?

How can one determine the adequacy of fan lifespan based on specific operational scenarios?

This article will systematically address and elucidate each of your inquiries.

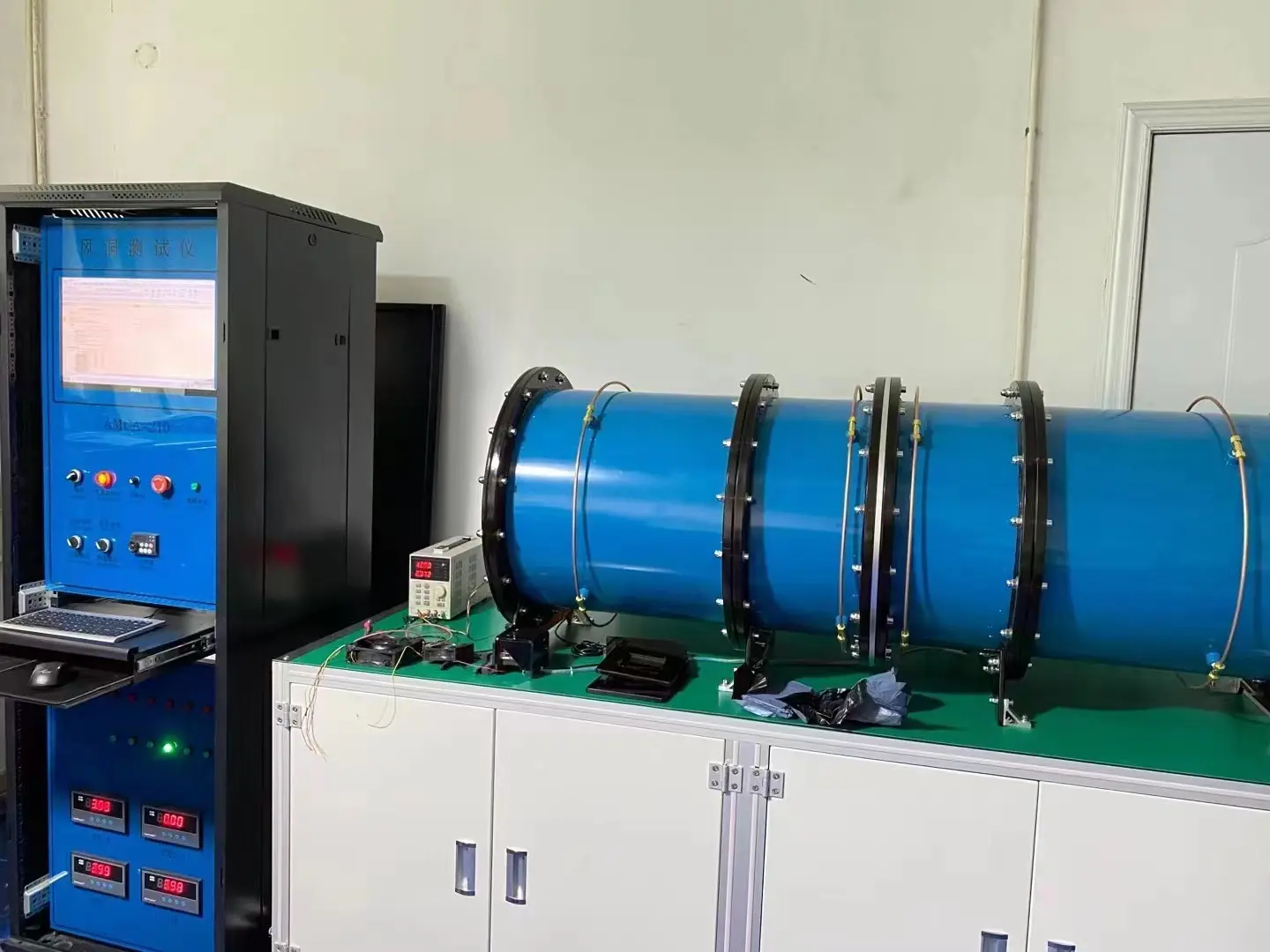

Why is differential pressure of utmost significance in the measurement of a fan's air flow?

In the measurement of air flow rate and static pressure in fans, differential pressure (Pn) constitutes a critical parameter that not only determines the magnitude of air flow but also facilitates an accurate assessment of fan performance. This paper presents an in-depth exploration of the Double Chamber Method for measuring the air performance curve of fans, elucidates the significance of differential pressure in measurement processes, and explicates this concept through specific formulas and application scenarios.

What potential does the RD signal hold in the context of intelligent control systems for cooling fans?

With the ongoing advancement in the intelligence of devices such as the Internet of Things (IoT), industrial automation systems, energy storage solutions, 5G communication infrastructure, and medical equipment, there is an increasing demand for enhanced "operational status visibility" and "fault prediction capabilities" in cooling fans. Conventional fans are typically designed to perform basic rotational functions, with some models providing tachometric feedback through FG signals. However, they lack the ability to accurately indicate whether the fan is genuinely operating under normal conditions. In this context, the RD signal (Rotation Detection signal) has emerged as a critical element facilitating the transition of cooling fans toward intelligent operation.

Full Metal Fan——15055

In a high temperature environment, have you ever worried about the durability of the fan? Now, you can rest assured to choose our all-Metal Fan-15055. It is designed to cope with extreme temperatures and can withstand ambient temperatures of over 100 degrees, making it an ideal companion for your high-heat products.

Which is more important for a fan, the maximum air flow or the maximum static pressure?

When choosing a cooling fan, we often come across two core parameters: maximum air flow and maximum static pressure . So, in practical applications, which parameter is more important? Does a higher air volume lead to better heat dissipation, or does a stronger static pressure make the fan play a greater role? Let's delve into an in-depth analysis.

How to choose a fan dedicated to LED lights?

With the widespread adoption of LED technology, fans, as a critical component of the LED lighting heat dissipation system, have garnered significant attention. Inadequate heat dissipation has emerged as a prevalent issue affecting LED lights, and the quality of the fan directly influences key factors such as lifespan, light attenuation performance, and operational stability. Given the extensive range of fan products available in the market, selecting an appropriate fan for LED lights to ensure prolonged and stable operation of the lamps can be challenging. Today, we present essential guidelines for choosing LED fans, ensuring you avoid common pitfalls and select the most suitable heat dissipation solution.

If the FG signal is unstable, is there any possibility of the cooling fan showing "fluctuations"?

In the operation monitoring of cooling fans, the FG signal (Frequency Generator Signal, frequency signal) is like the "heartbeat" of the fan, providing real-time feedback on the fan's rotational speed. It not only serves as a "barometer" of the fan's performance but also plays a crucial role in ensuring the safe operation of industrial equipment. However, when the FG signal becomes unstable, will the cooling fan experience "fluctuations" or even fail? This article will delve into the significant role of the FG signal and the impact of its instability on the fan.

What is the most accurate method for measuring air flow?

Airflow is one of the most crucial parameters in the development of cooling fans, ventilation systems, and industrial equipment. The air volume (CFM or m³/min) of a fan determines the cooling efficiency, and the accuracy of the measurement method directly affects the reliability of the test data. Currently, there are various methods for measuring airflow, including the Double Chamber Method, Open Jet Method, and Duct Method. So, which of these methods is the most accurate? How to choose the appropriate measurement method? Let's find out today!

What is the proper method for connecting only three out of the four wires of a cooling fan?

Cooling fans are typically designed with two, three, or four wires. Four-wire fans support PWM-based speed regulation and feedback, which makes them widely applicable in various scenarios. However, during actual installation, users may only require a subset of the fan's functionalities, leading to situations where a four-wire fan is connected using only three wires. This article aims to provide a detailed explanation of how to connect only three of the four wires of a cooling fan, along with important precautions to consider.

Can the FG (Fan Guard) signal output of the cooling fan be utilized for intelligent diagnostics?

In fields such as smart hardware, communication equipment, power systems, energy storage facilities, and industrial automation, the stability of cooling fans directly impacts the performance and safety of the entire system. Traditional methods for assessing fan status are primarily limited to binary logic—whether the fan is powered on or off, and whether it is rotating or not. However, this simplistic approach fails to meet modern equipment requirements for predictive maintenance and intelligent diagnostics. The FG signal (Frequency Generator), which is widely integrated into fans, is increasingly becoming a critical channel for achieving "fan-level intelligent diagnosis." It can not only provide real-time rotational speed data but also reflect changes in operational status, detect fault trends, and assist in health assessments. This raises the question: Can the FG signal truly support the task of "intelligent diagnosis"? This article will conduct an in-depth analysis from three perspectives: principle, methodology, and application.