News

Analysis of Selection Strategies and Consideration Factors for Cooling Fans in 2026

With the continuous upgrading of fields such as new energy equipment, intelligent manufacturing, robotics, energy storage systems, communication power supplies, plant factories, and industrial automation, Cooling Fans have evolved from traditional basic components to key components that significantly affect the reliability, operational stability, and overall lifecycle cost of the entire system.

The Ultimate Guide to Choosing the Perfect Cooling Fan for Your Needs

Our cooling fan range includes a variety of models designed to meet different environments and individual preferences. Ac Fans are ideal for larger spaces, providing strong airflow to quickly lower indoor temperatures. DC fans are energy efficient, making them perfect for those who want to enjoy a cool breeze while reducing their electricity bills. For users who need portability, our mini fans are compact and lightweight, perfect for use at home, in the office, or on the go.

One of the highlights of our cooling fans is the complete range of product specifications we offer. Each fan boasts a large airflow, ensuring optimal cooling performance. Furthermore, our fans operate with low noise, allowing you to enjoy a quiet environment free from machine noise. This is especially beneficial for those working from home or needing a quiet space to relax.

Durability is another key advantage of our cooling fans. With their exceptionally long lifespan, you can trust our products to serve you well for years to come. We understand that investing in cooling fans is a significant decision, and therefore we are committed to providing efficient and reliable products.

As an OEM and ODM manufacturer, we pride ourselves on our ability to customize products to meet our customers’ specific needs. We accept small-batch orders, making it easier for businesses and individual users to find the right fans without worrying about minimum order quantity restrictions. Our fast delivery cycle ensures you can enjoy the comfort of brand-new cooling fans without having to wait too long.

In short, whether you need a powerful AC fan, an energy-efficient DC fan, or a convenient mini fan, our extensive product range can meet your cooling needs. We remain committed to quality and customer satisfaction, striving to provide you with the perfect solutions for creating a cooler, more comfortable environment.

If you have any requirements related to cooling fans, please feel free to contact Shenzhen Fuqingda Electronic Technology Co., Ltd. Our company can provide you with comprehensive cooling solutions.

Is the EC fan DC or AC? What are the advantages of the EC fan?

EC fans are fan devices driven by DC motors. Their working principle is based on an internal electronic commutation system, which converts the input alternating current into direct current to drive the motor.

Compared to traditional AC fans, EC fans have higher energy efficiency, a wider speed adjustment range, and lower energy consumption.

Additionally, this type of fan supports intelligent control and enables precise air volume adjustment, making it suitable for applications with high requirements for ventilation systems.

The Ultimate Thermal Solution: Exploring Our High-Performance DC Fans

In today’s fast-paced world, efficient thermal solutions are crucial for maintaining optimal performance in a wide range of applications, from electronics to industrial machinery. With over 20 years of experience in manufacturing and sales, our company has become a leader in the cooling fan industry, providing high-quality DC fans that sell globally. We adhere to a philosophy of continuous improvement and have a comprehensive quality management system to ensure that every product meets the highest standards.

Frequently Asked Questions about Cooling Fans

Frequently Asked Questions about Cooling Fans

How to Choose the Appropriate Cabinet Cooling Fans

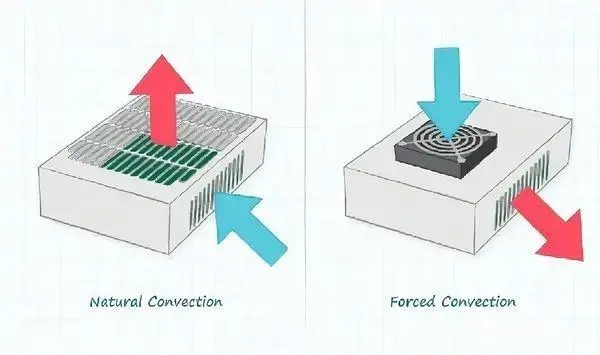

The selection of appropriate cabinet cooling fans plays a critical role in ensuring the reliable operation and longevity of electronic equipment. During the selection process, it is essential to conduct a comprehensive evaluation of multiple key factors, including thermal requirements, airflow and static pressure performance, bearing type, noise levels, control mechanisms, power supply specifications, dimensional compatibility, environmental resilience, and cost considerations. A well-informed and technically sound fan selection not only enhances system cooling efficiency and operational reliability but also minimizes failure rates and extends equipment service life. This paper provides a systematic and detailed examination of each of the aforementioned technical parameters and application criteria.

How to assess whether a cooling fan meets technical standards

The cooling fan serves as a critical thermal management component in electronic devices and industrial machinery, with its performance and quality directly influencing the operational stability, service life, and safety of equipment. Whether in the context of system assembly, equipment maintenance, or procurement and selection processes, assessing compliance with technical standards is an essential and integral requirement. This article presents a systematic and practical evaluation framework from two perspectives: testing methodologies for key performance indicators and visual inspection techniques for product quality assessment. The objective is to enable users to effectively mitigate potential risks associated with substandard cooling fans.

Understanding fan types is essential for achieving precise thermal management—A classification of cooling fans

When selecting a cooling fan for equipment, one may find it challenging to navigate the wide array of available products. A fan that performs effectively in a desktop computer enclosure may be inadequate for meeting the thermal requirements of a laptop. This discrepancy arises because cooling fans do not constitute a homogeneous product category; rather, they represent a diverse family of devices developed according to distinct operating principles, technical specifications, and application contexts. A clear understanding of their classification framework is therefore essential to overcoming information overload from excessive parameters and enabling accurate, application-specific selection.

Why do 3D printers need to be equipped with a dual-fan system?

For 3D printing enthusiasts, one of the most frustrating experiences is encountering a sudden nozzle clog during the printing process or observing warping and deformation at the base of the model as it nears completion. The root cause of these issues often lies in an underappreciated yet critical component—the cooling fan. Unlike conventional devices, where a single fan may suffice, the dual-fan configuration employed in 3D printers is not redundant; rather, it represents an engineered solution specifically designed to meet the precise thermal management demands of the additive manufacturing process. This setup serves as a key factor in ensuring print stability and dimensional accuracy. The absence of either fan may compromise print integrity, potentially resulting in the loss of hours of work.

What factors should be considered when choosing a cooling fan?

Cooling fans are extensively employed across a wide range of industries, with performance requirements varying considerably depending on the specific application. For example, the medical equipment sector necessitates fans characterized by ultra-low noise levels and extended service life, outdoor communication systems require fans with waterproof capabilities, while industrial enclosures and autonomous vehicles demand high airflow cooling solutions. Consequently, the selection process must take into account a comprehensive set of technical specifications and environmental adaptability factors. The following section provides a detailed examination of these critical considerations based on application-specific requirements.