Industry News

How to Select Axial Flow Fans, Centrifugal Fans, and Blowers?

I. Introduction

In industries such as manufacturing, telecommunications, healthcare, and renewable energy, the cooling system serves as a critical component for ensuring the stable operation of equipment. Whether it is precision medical instruments or high-power communication base stations, overheating can lead to performance degradation or even equipment failure. Consequently, the appropriate selection of Fan types is essential for extending equipment lifespan (approximately 50,000 hours) and achieving energy efficiency. This article aims to provide a comprehensive understanding of the following:

• Axial Fans

• Centrifugal Fans

• Blowers

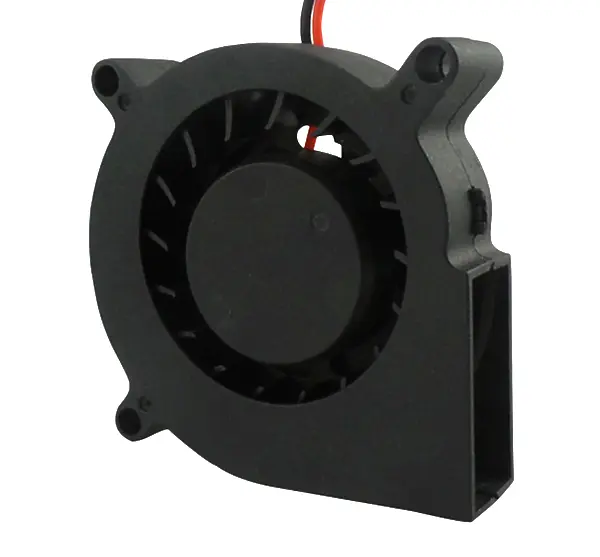

6025 High Efficiency DC Fan

With the rapid development of modern technology, cooling solutions have become increasingly important. We proudly introduce the 6025 high-efficiency DC fan, a compact yet powerful design specifically designed for devices requiring high exhaust volume and limited installation space. Measuring only 60 x 60 x 25 mm, it delivers a powerful 48 CFM of airflow at up to 10,000 revolutions per minute, ensuring your device remains cool even under heavy loads.

Why are cooling fans indispensable in medical equipment? Ensuring the lifeline remains stable during critical moments.

In the ICU, beside ventilators, in front of CT scanners in radiology departments, or under monitors in operating rooms, each medical device serves as a guardian of patient lives. Behind the stable operation of these sophisticated instruments lies a frequently overlooked yet critical component—the cooling fan.

While it does not directly interact with patients nor output data results, it functions as the "thermal management core" of medical equipment. Inadequate heat dissipation can lead to diminished device performance, system failures, interrupted diagnostics, and even medical accidents. This article provides an in-depth analysis of why cooling fans are indispensable for medical devices and offers guidance on selecting professional fan products that meet medical standards.

How to quickly diagnose and fix cooling fan problems caused by an RD signal failure?

In high-load scenarios such as industrial equipment, servers, and communication base stations, the stability of Cooling Fans is directly correlated with hardware longevity and system safety. The RD (Rotor Detection) stall alarm signal, serving as a core monitoring mechanism for fan malfunctions, provides real-time feedback on rotor operational status, thereby mitigating overheating risks caused by fan stalling. Drawing upon two decades of R&D and production expertise from Shenzhen Fuqingda Electronics Technology Co., Ltd., this paper elucidates rapid identification and resolution strategies for RD signal malfunctions.

How does the cooling fan with an integrated temperature sensor detect temperature?

In electronic devices, cooling fans serve not only to reduce temperature but also function as temperature monitors. With advancements in technology, many modern cooling fans are now equipped with built-in temperature sensors, enabling real-time detection of ambient or device temperatures and facilitating corresponding adjustments. This raises the question: how do these integrated temperature sensors "perceive" temperature, and how do they influence the operational state of the fans?

Still worried about EV charger heat dissipation? The FQD IP68 dustproof and waterproof fan is the perfect solution!

During operation, charging piles generate a significant amount of heat. If the heat dissipation is inadequate, it may not only reduce charging efficiency but also pose serious safety hazards. Therefore, effectively addressing the heat dissipation issue of charging piles has become a key focus in the industry.

More than airflow, it's protection: Cooling fans keep your devices running smoothly

In high-load servers, 24/7 operational 5G base stations, precision medical equipment, as well as everyday devices such as laptops and smart home appliances, cooling fans consistently safeguard the core components of these devices. Beyond merely "blowing air," they serve as critical components that provide thermal protection, performance assurance, and longevity support for electronic equipment. This article will delve into the roles, application scenarios, technological highlights, and key selection criteria of cooling fans, while introducing how Fuqingda Electronics offers comprehensive thermal management solutions.

How to Extend the Service Life of High Protection Level Cooling Fans?

In the fields of industrial applications, telecommunications, and outdoor electronic equipment, high-protection-level cooling fans (e.g., IP54, IP65, IP68) have emerged as critical components for ensuring system stability and reliability. However, despite their exceptional dustproof and waterproof capabilities, improper usage and maintenance can significantly reduce their operational lifespan. This article unveils six essential techniques to maximize the value and performance of high-protection-level cooling fans.

Why does the oil mist-resistant fan exhibit a significantly extended operational lifespan?

In high-intensity industrial environments such as factory automation, CNC machine tools, and industrial robotics, oil mist poses significant challenges to the stability and longevity of cooling fans. Conventional cooling fans, when exposed to oil mist, are prone to insulation degradation, circuit shorting, and rotational inefficiency, leading to diminished thermal management performance, frequent malfunctions, and even equipment downtime.

Is there a solution to this problem through oil proof fans?

Today, we present a comprehensive analysis of an industry-acclaimed industrial-grade thermal management solution: the oil proof fan manufactured by Fuqingda Electronics. This innovative product is designed to address thermal dissipation challenges at their source in oil mist-laden environments.

What is the typical lifespan specification for the cooling fan in a frequency converter?

In electrical automation systems, the Variable Frequency Drive (VFD) serves as a critical component, extensively utilized in industrial control, air conditioning systems, machine tools, elevators, water pumps, and other equipment. However, it is noteworthy that over 30% of VFD malfunctions are attributed to the expiration of fan lifespan without timely replacement.

This raises two pivotal questions:

What should be the standard lifespan of a VFD cooling fan?

How can one determine the adequacy of fan lifespan based on specific operational scenarios?

This article will systematically address and elucidate each of your inquiries.