Industry News

How to assess whether a cooling fan meets technical standards

The Cooling Fan serves as a critical thermal management component in electronic devices and industrial machinery, with its performance and quality directly influencing the operational stability, service life, and safety of equipment. Whether in the context of system assembly, equipment maintenance, or procurement and selection processes, assessing compliance with technical standards is an essential and integral requirement. This article presents a systematic and practical evaluation framework from two perspectives: testing methodologies for key performance indicators and visual inspection techniques for product quality assessment. The objective is to enable users to effectively mitigate potential risks associated with substandard cooling fans.

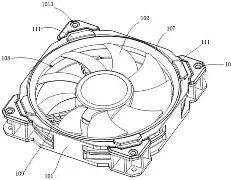

Why do 3D printers need to be equipped with a dual-fan system?

For 3D printing enthusiasts, one of the most frustrating experiences is encountering a sudden nozzle clog during the printing process or observing warping and deformation at the base of the model as it nears completion. The root cause of these issues often lies in an underappreciated yet critical component—the cooling fan. Unlike conventional devices, where a single fan may suffice, the dual-fan configuration employed in 3D printers is not redundant; rather, it represents an engineered solution specifically designed to meet the precise thermal management demands of the additive manufacturing process. This setup serves as a key factor in ensuring print stability and dimensional accuracy. The absence of either fan may compromise print integrity, potentially resulting in the loss of hours of work.

What factors should be considered when choosing a cooling fan?

Cooling fans are extensively employed across a wide range of industries, with performance requirements varying considerably depending on the specific application. For example, the medical equipment sector necessitates fans characterized by ultra-low noise levels and extended service life, outdoor communication systems require fans with waterproof capabilities, while industrial enclosures and autonomous vehicles demand high airflow cooling solutions. Consequently, the selection process must take into account a comprehensive set of technical specifications and environmental adaptability factors. The following section provides a detailed examination of these critical considerations based on application-specific requirements.

Analysis of Common Issues in Cooling Fans

Heat dissipation fans are widely utilized in industrial production and everyday applications. The reliable operation of various equipment typically depends on effective thermal management provided by these cooling fans. Should a heat dissipation fan fail, the stability and service life of the associated equipment may be significantly compromised. What are the primary factors contributing to the malfunction or abnormal operation of heat dissipation fans?

As a professional manufacturer of cooling fans, FQD Company hereby presents the following responses to the relevant inquiries.

What are the key factors affecting the quality of cooling fans?

The quality of a cooling fan is not solely determined by rotational speed or airflow volume, but rather depends on a combination of critical technical factors. This section provides a concise overview of the key elements influencing cooling fan performance. These include material properties, structural design, manufacturing precision, bearing type, speed stability, and noise control. Collectively, these factors significantly affect the fan's thermal dissipation efficiency, operational reliability, and service life, serving as essential indicators for assessing its overall performance.

High-Performance Industrial-Grade Cooling Fan – Model 8025

In sectors such as energy storage, photovoltaics, and electronic equipment, stable and efficient thermal management is critical to ensuring the long-term reliable operation of systems. The FQD 8025 DC cooling fan, featuring exceptional performance design, comprehensive functional capabilities, and broad application adaptability, has emerged as a highly competitive thermal solution within the industry, delivering efficient and reliable cooling performance for a wide range of equipment.

What factors contribute to the broader applicability of DC fans relative to AC fans?

In modern electronic devices, cooling fans are widely employed. However, the selection process often involves a critical decision between DC and AC power supply options. This paper systematically examines the key differences based on the inherent characteristics of each type and provides a detailed analysis of the technical advantages associated with DC fans.

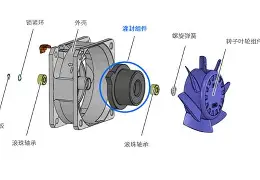

Do bearings significantly impact the service life of cooling fans?

When selecting a cooling fan, it is essential to consider the type of bearing employed, as it significantly influences the fan's service life. This article provides a comprehensive analysis of this issue. Bearings serve as the core component of a cooling fan, directly determining critical performance parameters such as operational lifespan, noise levels, and cost. An inappropriate selection may result in excessive noise during operation or premature failure after extended use.

How many of these concealed functionalities in custom cooling fan solutions are you aware of?

In specialized applications such as industrial machinery, outdoor electronic systems, and instrumentation in high-humidity environments, conventional cooling fans frequently fall short of operational requirements. In such cases, customized functional enhancements enable cooling fans to overcome environmental challenges, delivering improved thermal performance with greater reliability and longevity. The following section provides a comprehensive analysis of the most practical customization options available for cooling fans, aimed at ensuring optimal alignment with specific application conditions.

Blowing versus suction: Which airflow configuration is more effective for cooling fan performance?

The cooling fan is a commonly used thermal management component in electronic devices. Its main function is to guide external airflow, enhance air circulation, promote convective heat transfer, and effectively expel the accumulated heat inside the device to the external environment. During actual operation, the cooling fan can adopt either the blowing mode or the suction mode. These two airflow organization methods have different influence characteristics on the heat dissipation performance. Therefore, it is worth conducting a systematic analysis and comparison to determine the specific impact degree of the blowing and suction modes on the overall heat dissipation effect.