AC 8038 80*80*38 mm Small Size Big Air Flow AC Axial Fan

Product ParameterParameter

| Specifications | ||||||||||

| Model | Bearing System |

Rated Voltage (V) |

Freq (Hz) |

Current (A) |

Input Power (W) |

Speed (RPM) |

AirFlow (CFM) |

Pressure (mmH²o) |

Noise (dBA) | Weight (g) |

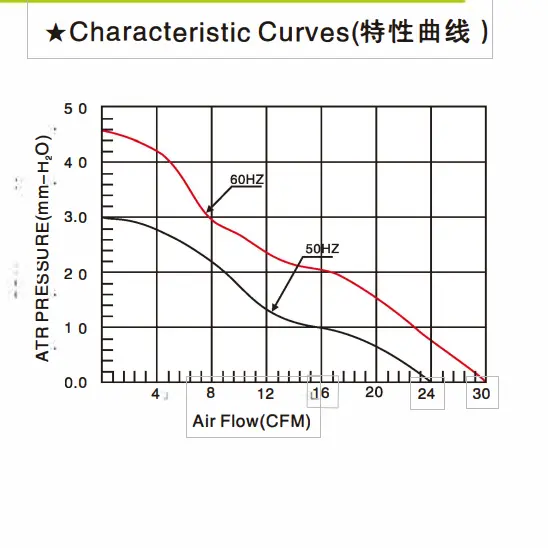

| 8038HS/B1 | Sleeve/Bal | 110 | 50/60 | 0.15/0.13 | 17.0/15.0 | 2400/2900 | 23/28 | 2.8/4.4 | 34/36 | 300 |

| 8038MS/B1 | Sleeve/Ball | 110 | 50/60 | 0.10/0.11 | 13.0/10.0 | 1900/2400 | 20/23 | 2.0/2.2 | 27/34 | 300 |

| 8038HS/B2 | Sleeve/Bal | 220 | 50/60 | 0.08/0.06 | 17.0/15.0 | 2400/2900 | 23/28 | 2.8/4.4 | 34/36 | 300 |

| 8038MS/B2 | Sleeve/Bal | 220 | 50/60 | 0.06/0.05 | 13.0/10.0 | 1900/2400 | 20/23 | 2.0/2.2 | 27/34 | 300 |

Product introductionintroduction

The small axial fan boasts low power consumption, fast heat dissipation, low noise levels, energy efficiency and environmental friendliness. Due to its compact size, it finds extensive applications in metallurgy, chemical industry, light industry, food processing, medical equipment and civil engineering for ventilation or heat dissipation purposes. When the casing is removed, it can function as a free fan or be installed at intervals within long exhaust pipes to increase wind pressure. Axial fan blades operate similarly to aircraft wings but instead move air rather than lift upward on the wing to support an aircraft's weight. When starting up the axial fan motor draws 5-6 times more current than its rated value which not only affects its service life but also consumes more electricity. Motor selection during system design includes a certain margin with fixed speed; however actual use may require running at lower or higher speeds necessitating frequency conversion transformation. Inverters enable soft start of motors by changing input voltage frequency while providing over-current/voltage/overload protection functions thereby achieving energy-saving speed regulation. Classification by material includes steel fans fiberglass fans plastic fans PP fans PVC fans magnesium alloy fans aluminum fans stainless steel fans among others while classification by use encompasses explosion-proof anti-corrosion temperature special axial flow and other types based on specific requirements such as pipe type wall type post type fixed rain/dust proof mobile motor external etc.

Die-cast aluminum housing

Glass fiber reinforced plastic: Impeller and housing PBT are UL 94V0 rating

Impedance protected

Leader wire or terminal is available

Operating temperature:

Ball bearing: -30℃to +75℃

Sleeve bearing: -10℃to +70℃