0102030405

4028 40*40*28 mm Big Air Flow Small Size Dc Cooling Fan

Product ParameterParameter

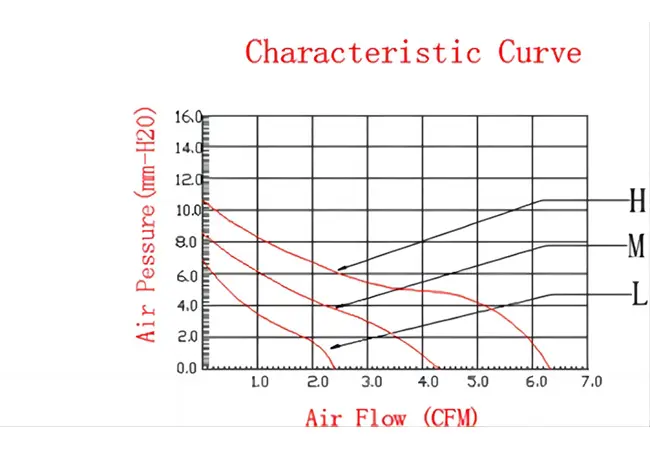

| Model | Bearing Type | Rated Voltage | Current | Speed | Air Flow | Pressure | Noise | Weight | |

| VDC | A | RPM | CFM | mmH₂O | dBA | g | |||

| FD2440287S/B | Sleeve/Ball | 24 | 0.13 | 9000 | 13.30 | 9.51 | 38.2 | 32 | |

| FD2440285S/B | 0.08 | 7000 | 10.40 | 7.40 | 33.5 | ||||

| FD2440283S/B | 0.05 | 5000 | 7.43 | 5.28 | 25.6 | ||||

| FD1240287S/B | Sleeve/Ball | 12 | 0.18 | 9000 | 13.30 | 9.51 | 38.2 | ||

| FD1240285S/B | 0.15 | 7000 | 10.40 | 7.40 | 33.5 | ||||

| FD1240283S/B | 0.12 | 5000 | 7.43 | 5.28 | 25.6 | ||||

Product introductionintroduction

1. DC motors offer the advantages of rapid response, high starting torque, and the capability to deliver rated torque from zero to rated speed. However, these very advantages also pose as disadvantages due to the necessity of using carbon brushes and slip rings in order to maintain a constant 90° between the armature field and rotor field. The generation of sparks and carbon powder during motor operation can lead to component damage and usage limitations. On the other hand, AC motors, which do not require carbon brushes or slip rings, are maintenance-free, durable, and widely utilized. Nevertheless, achieving equivalent performance to DC motors requires complex control technology for regulating their performance. The advancement of semiconductors has significantly increased power component switching frequency while also enhancing motor drive performance. Additionally, with the increasing speed of microprocessors enabling control of AC motors in a rotating two-axis rectangular coordinate system and appropriate regulation of current components in both axes allows for similar control capabilities as that of DC motors.

2. Operating ambient temperature

Ball bearing: -30 to +75℃

Sleeve bearing: -10 to +70℃

3. Insulation resistance:

10 meg ohms min, at 500V DC (between frame and terming)

Dielectric strength: 5mA max at 500V/AC/60Hz one minute (between frame and terminal)

4. Functions: Frequency generator signal option

5.Rated voltage: 24V 12V .5V